Description

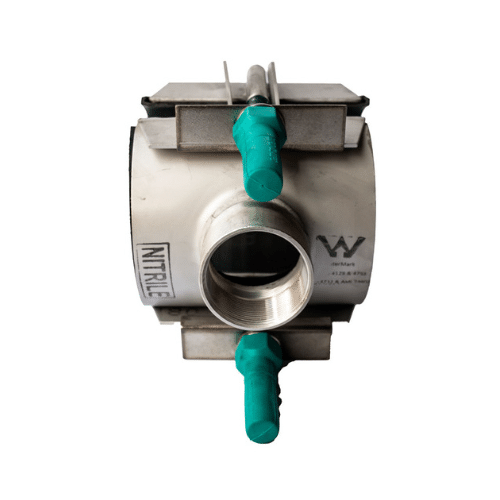

Rapids CT tapping saddles offer a reliable solution for a branch connection from existing pipes, without having to shut off supply (Hot-Tapping). CT tapping saddles strong stainless steel shells reinforce the pipe at the connection point and Rapids patented designed gasket provide a seal at the tapping point for both positive and negative pipe pressure.

- Locking Washer Plate: Stainless Steel Type 316. Locks into position for easy tightening of nuts.

- Lugs: Stainless Steel Type 316. MIG-welded to receiver bar and fully passivized after welding. Leading edge is rounded to prevent them from catching bolt bars during installation.

- Shell: Stainless Steel Type 316. 2B finish. Fully passivized after welding.

- Bolts: Stainless Steel Type 316. Thread-rolled for strength and coated to prevent galling. Bolts are MIG-welded to the receiver bar and fully passivized after welding.

- Nuts/Washers: Stainless Steel Type 316

- Receiver Bars: Stainless Steel Type 316. TIG-welded to shell to form a strong fusion and fully passivized after welding.

- Gasket: Nitrile, to AS1646 and AS4020 standards specially formulated for water service, gas and oil. The gasket is specially designed with a static seal and a dynamic lip seal. Also incorporated into the seal is an internal stainless steel retaining disc, which prevents the seal and mat from extruding out, under extreme internal pressure. The specially designed seal allows for pipe outside diameter changes, caused by pressurizing and depressurizing of the pipe.

- Tappings: Stainless steel Type 316. BSP parallel threaded socket. ATSM A312M, AS1722.1 Rp

- Max Operating Pressure: 1600kPa (PN16)

- Temperature Range: 0°C – 60°C